5 AXIS MILLING CNC MILLING

CNC milling and drilling of small and large production runs. Our 5th axis machine gives us the ability to machine complex shapes in a single set-up.

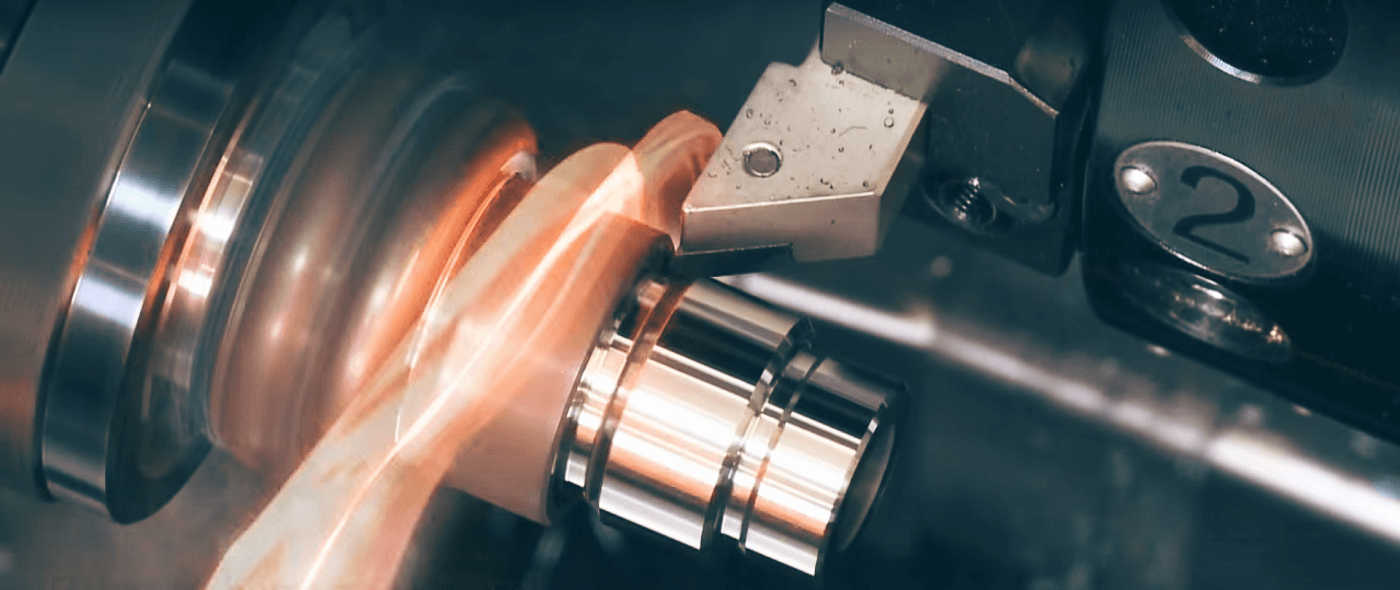

HARD TURNING

CNC turning of parts up to 39 inches in diameter & automatic bar feeder work on materials up to 3 inches in diameter. We specialize in the turning of hard & exotic materials. With hard turning, we can achieve greater accuracy while attaining higher productivity then with grinding alone.

CNC GRINDING

Precision CNC I.D./O.D grinding. Precision manual I.D. grinding. Precision centerless through feed grinding (3 1/2’ max diameter). Precision centerless end feed grinding (3’max length x 6’ max diameter).

AUTOMATIC HONING

Production honing of hard and soft materials to close tolerances and finishes. With the use of high precision Sunnen machines, Powill is able to hold tolerances as low as .0002" with sizes ranging from .060" Dia up to 6" in diameter.

DEEP HOLE GUN DRILLING

Deep hole drilling from Ø.125" to Ø1.625" diameter x 28" deep. We gun drill aerospace and commercial hardware from space-age alloys of titanium, stainless steels and Inconels, as well as steel and aluminum.

WIRE EDM

CNC Wire EDM is a method to cut conductive materials with a thin electrode that follows a programmed path. The electrode is a thin wire usually made of brass. Typical diameters range from .004"-.012" although smaller and larger diameters are available. The hardness of the work piece material has no detrimental effect on the cutting speed making wire EDM an excellent choice for hardened materials. The wire is charged to a voltage and surrounded by de-ionized water. When the voltage reaches the correct level, a spark jumps the gap and melts a small portion of the work piece. The de-ionized water cools and flushes away the small particles from the gap. Complex configurations can be achieved with quick turn times as no cutting tools are required.

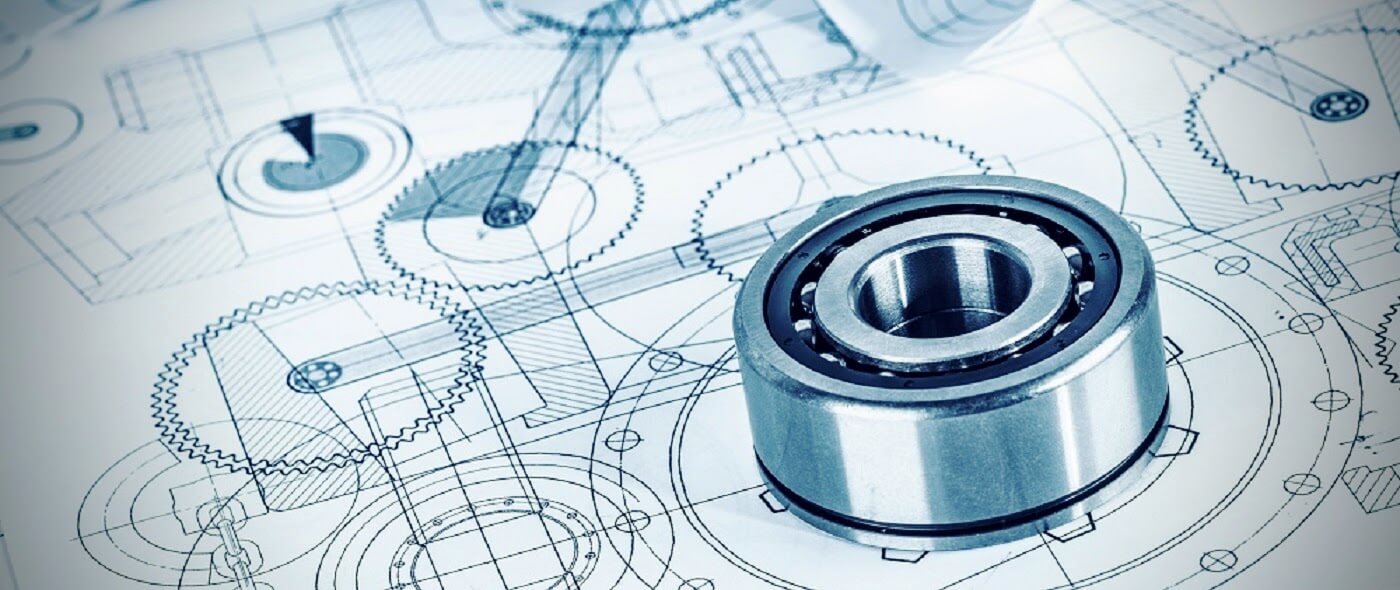

ENGINEERING TEAM

Powill's Skilled and innovative Engineering Department relies on their combined 120 years of experience, while using the latest in software developments to help take your project from concept to conception. Powill Manufacturing starts from the ground up to deliver parts which will meet or exceed your requirements. Let us help with your new Product development.

Powill Uses GibbsCAM to create the cutter paths for our CNC Machines. This allows us to program off of an electronic solid model created in any of the design softwares currently available. Building cutter paths from solid models not only saves time, but is more accurate. This allows us to simulate and optimize machining while still in the engineering phase.

INSPECTION DEPARTMENT

All final inspection is done in our temperature and humidity controlled clean room. The below listed equipment is maintained in this room to ensure constant accuracy.

ASSEMBLY AND TESTING

Powill is ready to meet all of your assembly needs.

Honeywell certified for GPS-6007 Valve seat impacting, lapping, leak testing.

Bearing installation, swaging, staking, sizing, press-fit and shrink fit.

Lee plug installation.

Helicoil insert, Keensert,and threaded fastener installation.

Primers, Sealant, Loctite, Silicone and Adhesive sealing to most Aerospace Specs